Toshiba

ScanSure

Seamless Validation

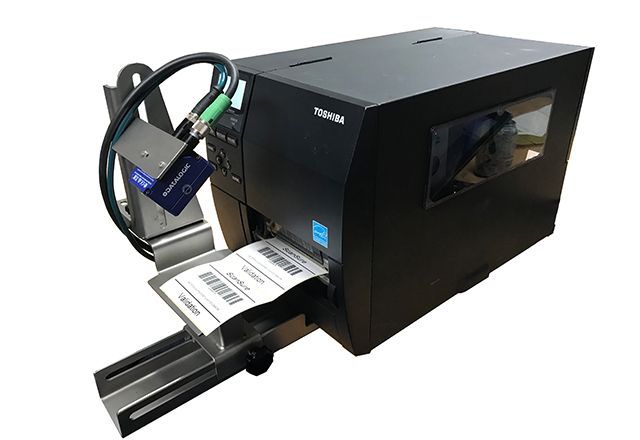

The TOSHIBA ScanSure is an all-in-one, inline barcode validation solution that ensures barcodes are readable and accurate the moment they are printed. Designed to integrate seamlessly with Toshiba’s B‑EX4 and B‑EX6 industrial printers, ScanSure elevates print quality control by validating each label at the point of creation—minimizing misprints, enhancing traceability, and helping you avoid costly recalls or rework.

Zero Tolerance for Bad Barcodes: Real-time validation ensures every printed label is scannable, reducing supply chain errors.

Automated Quality Assurance: Void Mode saves time by auto-stripping and reprinting invalid labels, keeping operations on track.

Easy Integration: Mounts directly to existing B-EX printers—no separate validation setup required.

Live Monitoring: Web interface provides real-time insight into label print quality, with flexible validation mode control.

Reliable and Compact: Small form factor and industrial-grade performance make it ideal for demanding production environments.

Fast Mode & Void Mode Support: Offers two modes—Fast Mode for real-time barcode validation and Void Mode for automatic removal and reprinting of failed labels.

Built-in Camera & Validation: Equipped with a variable focal-length camera (Datalogic Matrix 220), it verifies readability, content, and barcode compliance, supporting ISO/IEC scoring and ANSI grading for 1D and 2D codes.

Compact, Mountable Design: Compact dimensions (78 × 47 × 38 mm) and lightweight (173 g, excluding mount and cables) make it easy to attach to printers without disrupting production flow.

Seamless B-EX Integration: Compatible with Toshiba B-EX4 and B-EX6 series printers, though Void Mode requires the ribbon-save module on the printer.

Advanced Setup & Web Interface: Includes fast auto-setup for focus, exposure, and code learning. After setup, the web interface provides live image previews, mode switching, and remote configuration.

Industrial Validation Standards: Relies on industry-leading barcode quality standards including ISO/IEC 15416, ISO/IEC 16022, ISO/IEC 15415, and AIM-DPM (ISO/IEC 29158) for reliable validation.

Wide Operating Range: Engineered to function reliably in industrial environments, with an operating temperature range of –10 °C to 50 °C.

| Fast Mode | Void Mode |

| Check readability | Yes | Yes |

| Validate barcodes | Yes | Yes |

| Validate content | Yes | Yes |

| Automatic voiding | - | Yes |

| Focus | Variable focal length | |

| Package includes | Datalogic® Matrix 220, camera support, power cable, ethernet adaptor, printer interface cable. (Ethernet cable required but not included) | |

| Dimensions & Weight | 78mm x 47mm x 38mm 173g (excluding mounting system and cables) | |

| Compatible Toshiba systems | B-EX4 series, B-EX6 series (Void Mode not valid on any printer that does not have “ribbon-save module” - Not applicable with T2/T3/D2 models) | |

| Verification standards | 1D CQ Standard: ISO/IEC 15416 2D CQ Standard: ISO/IEC 16022/18004, ISO/IEC 29158 (AIM-DPM), ISO/IEC 15415 | |

| Operating temperature | -10 to 50°C (14 to 122 °F) | |